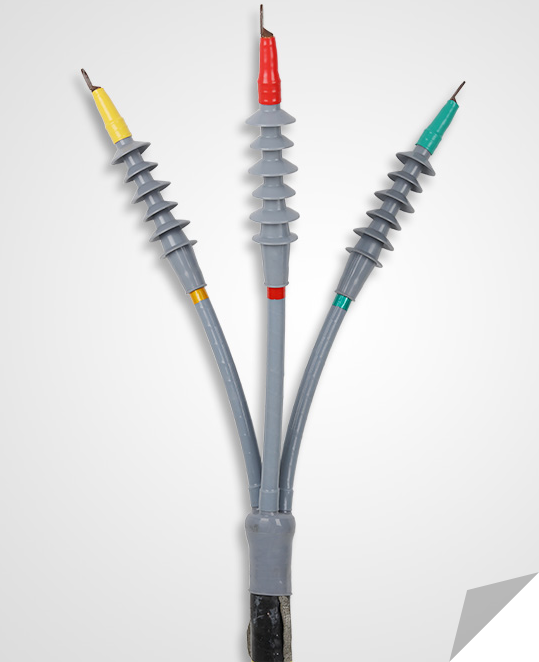

Different construction technology of Cold Shrink and Heat Shrink Cable Accessories

Cold Shrink Technology

1. Cold Shrink Cable Accessories avoid many human factors. When installing, cold shrink accessories only need to remove the plastic core inside then it can automatically shrink.It would not cause the uneven contraction of insulation pipe, so as to ensure the quality of construction.

2. Cold shrinkage is a procedure in which the accessories shrink from one end to the other. This procedure cannot be changed to ensure that no bubbles will appear during the shrinkage process.

3. In dangerous situations in the petrochemical industry, the installation of cold shrink accessories avoids the use of heat sources and becomes safe.

Heat Shrink Technology

1. Heat shrinkage is greatly affected by installation. Uneven heating will lead to uneven shrinkage thickness of the insulation tube, and even some parts do not shrink at all, which results in uneven shrinkage thickness, thin places prone to breakdown and other problems.

2. In the heating process of Heat Shrink Accessories, it is easy to burn the insulated tube because the degree of heating is not well mastered, which greatly affects the insulation performance of the insulated tube.

3. In the heating process, the Heat Shrink Accessories can be heated from one end to the other, or from the middle to the two ends, which is easy to lead to bubbles in the shrinkage process.

4. The use of heat sources such as open flame is prohibited in places such as petrochemical and chemical industries. If the risk increases when using, serious accidents may occur.

In the process of using

1. Cold Shrink Cable Accessories will keep synchronous respiration with the thermal expansion and cold contraction of it, so that the cable and accessories always maintain a good combination state.

2. Heat Shrink Cable Accessories will not change with the thermal expansion and cooling of the cable. Long-term operation is easy to lead to the gap between the cable and the accessories, leading to the occurrence of accidents.

Quality Comparing

1. The inherent advantages of cold shrink make the application of Cold Shrinkable Cable Accessories continue to develop towards high voltage. At present, there are 110KV Cold Shrink Cable Accessories.

2. The inherent shortcomings of the heat shrink cable accessories make it restricted for a long time in the application of the 35kV voltage level below. At 35kV voltage level, heat shrink cable accessories have become an important cause of frequent accidents in cable operation.

The inherent advantages of Cold Shrink Cable Accessories have driven continuous development, enabling their application at increasingly higher voltage levels. Notably, 110kV Cold Shrink Cable Accessories have emerged as a testament to the progress made in this field. The reliable installation process, bubble-free shrinkage, and safety benefits make Cold Shrink Accessories a preferred choice in demanding applications.

In the dynamic landscape of cable accessories technology, choosing between Cold Shrink and Heat Shrink Cable Accessories remains crucial. Cold Shrink Accessories excel in simplicity, safety, and resilience, while Heat Shrink Accessories, with ongoing innovations, can find their niche in specific applications where careful heating control can be assured.

The advancements in Cold Shrink and ongoing innovations in Heat Shrink Cable Accessories have transformed cable installation and performance. As technology continues to evolve, it's imperative to select the most suitable solution based on installation conditions, industry requirements, and safety considerations, ultimately ensuring the seamless operation of vital electrical systems.

English

English 简体中文

简体中文